In today's competitive landscape, manufacturers operate on razor-thin margins. Every inefficiency, every moment of downtime, directly impacts profitability.

The struggle is real:

Are you tired of disjointed software systems causing miscommunication and costly mistakes?

Do traditional methods leave you vulnerable to defective products and production delays?

Are unexpected equipment failures disrupting your production schedules and eroding your bottom line?

Is your quality control system time-consuming and error-prone?

Are inventory management and resource planning constant challenges?

Do maintenance issues result in costly downtime and disruptions?

Odoo Manufacturing offers comprehensive solutions beyond these pain points. Its integrated ERP platform ensures seamless coordination across departments, enhancing accuracy and productivity. For manufacturers seeking to streamline operations, drive efficiency, and maximise profitability, Odoo Manufacturing is an indispensable tool.

Why choose Odoo for Manufacturing?

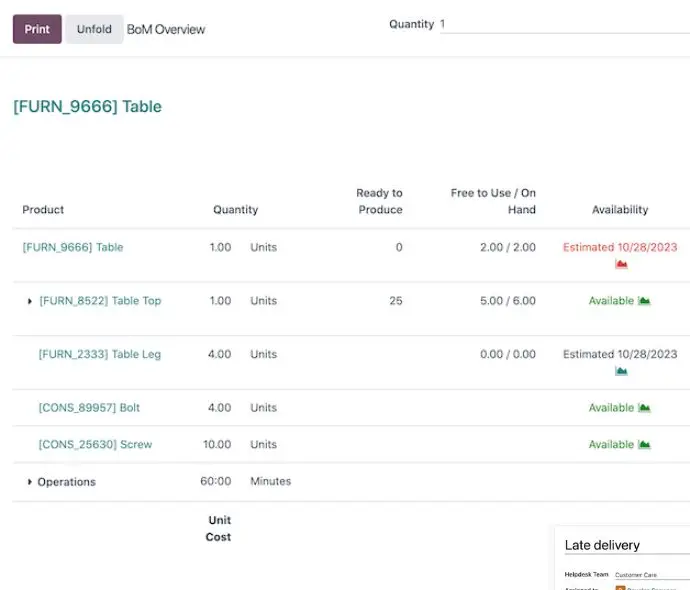

Single BOM for Variants

Manage product variations with a single Bill of Materials (BOM), reducing data entry and complexity.

Backward Scheduling

Schedule production tasks based on desired completion date, ensuring on-time delivery.

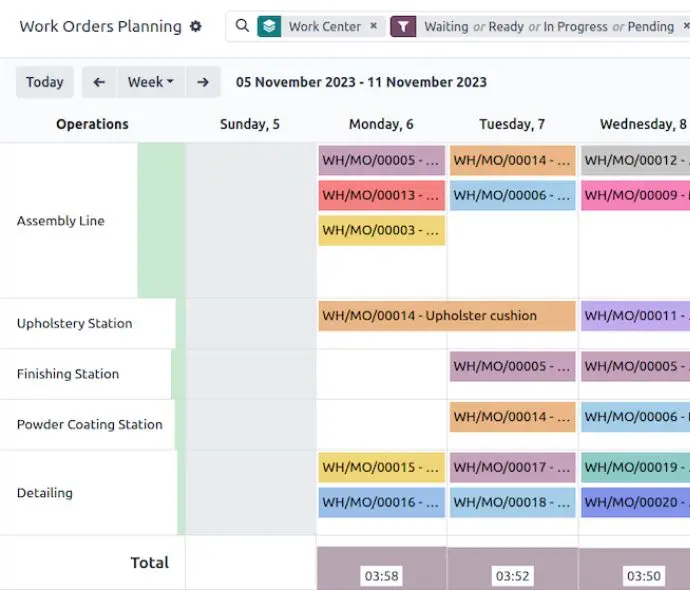

Workcenter Capacity Planning

Allocate work tasks based on real-time capacity of each work area, optimising production flow.

Byproduct Management

Efficiently track and manage byproducts generated during production, minimising waste.

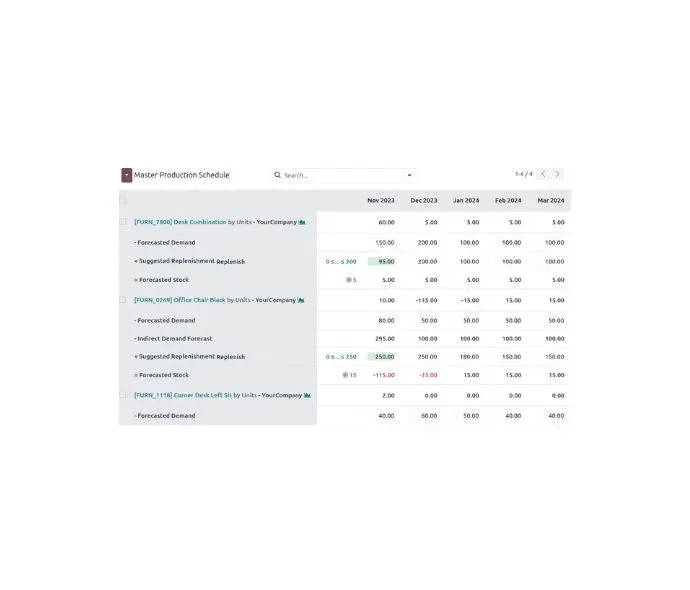

Real-Time MRP Simulation

Simulate production scenarios with real-time data, ensuring optimal inventory levels and avoiding stockouts.

Integrated Barcode Scanning

Streamline production processes with barcode scanning for material tracking, reducing errors.

Flexible Work Orders

Edit work orders even after creation, allowing for adjustments based on real-time needs.

Multi-Level Routing

Define flexible production workflows with multiple stages and options for different product types.

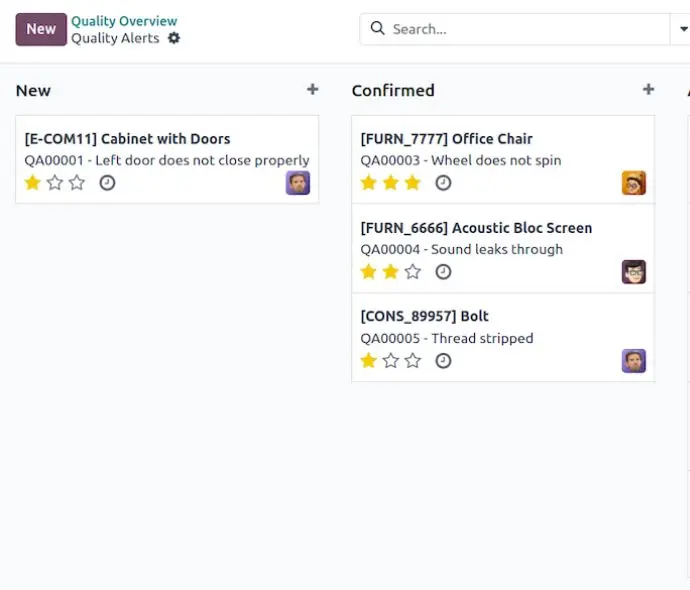

Quality Control Integration

Seamlessly integrate quality checks at various production stages, ensuring product quality throughout the process.

Odoo manufacturing features

Comprehensive Manufacturing Integration

MRP, MES, PLM, Quality, Shop Floor, and Maintenance capabilities.

All-in-one platform for streamlined operations and efficient production management.

Simplifies complex manufacturing processes with integrated tools and real-time insights.

Enhances productivity and reduces operational costs across the manufacturing lifecycle.

Seamlessly connects production planning, quality control, and maintenance for optimal efficiency.

Advanced Planning and Scheduling

Real-time simulated operations with capacity planning and cost control.

Just-in-time replenishment proposals for efficient inventory management.

Utilises finite capacity planning for scheduling manufacturing orders.

Fine-tune schedules easily with intuitive Gantt chart visualisation.

Plan resources effectively to meet production deadlines and optimise workflow.

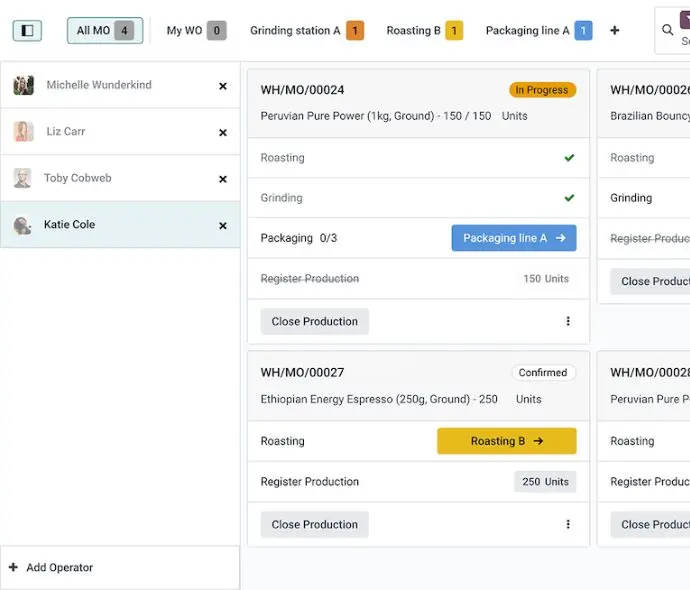

Enhanced Shop Floor Management

Mobile barcode application for instant data capture and efficient operations.

Tablet-optimised dashboard for organising work centres, workers, and quality tests.

Facilitates paperless operations with digital worksheets and instructions.

Supports Six-Sigma level quality control with statistical analysis capabilities.

Enables instant feedback and waste reduction through seamless communication channels.

Robust Product Lifecycle Management (PLM)

Version control and track changes with detailed product and ECO management.

Document management directly linked to Bills of Materials (BoM) and routings.

Manage engineering changes efficiently with a visual Kanban process.

Store plans and documents securely for easy access and revision history.

Enhances teamwork and creativity through customisable product choices.

Comprehensive Maintenance and Quality Control

Automated quality checks triggered during manufacturing processes.

Statistical process control (SPC) deployment for consistent product quality.

Maintenance requests are automated based on performance indicators (KPIs).

Schedule and track maintenance operations with a calendar interface.

Monitor overall equipment effectiveness (OEE) for optimised production efficiency.

It's time to conquer inventory chaos, eliminate data silos, and streamline production with a unified approach